Working Load Capacity

A fiberglass cable tray's working load capacity shows how much static cable weight it can support. With a minimum safety factor of 1.5, it is comparable to destructive load capacity.

| Width of Cable Tray |

Side Rail |

Load Kg/Mtr. For Support span 2.0 Mtr. |

| 150mm |

75 |

35 |

| 300mm |

75 |

65 |

| 450mm |

100 |

85 |

| 600mm |

100 |

95 |

| 750mm |

100 |

125 |

| 900mm |

150 |

155 |

At the middle of the span, there is a 70 kg concentrated static load.

As per NEMA Loading Standards:

| Load |

Lb/ft. |

Kgs/Mtr. |

| A |

50 |

74 |

| B |

75 |

111 |

| C |

100 |

148 |

| Side Rail |

Load Class |

| 75 |

8A |

| 100 |

8C, 12C, 16A |

| 150 |

12C, 16B, 20A, 20C |

8, 10, and 12 are in feet of support.

Temperature Effect

Continuously exposing fiberglass to high temperatures reduces its strength qualities. Working loads must be decreased in accordance with the following:

| Temp. in F |

75 |

100 |

125 |

150 |

175 |

200 |

| Approx. % of Strength |

100 |

90 |

78 |

68 |

60 |

52 |

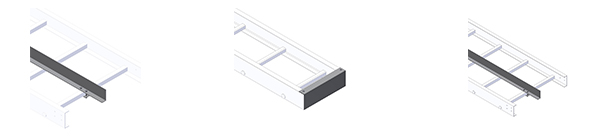

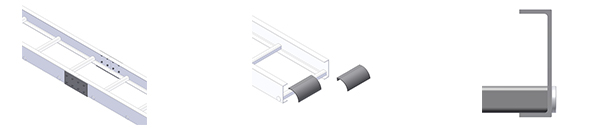

Installation Instructions

The National Electric Code and NEMA Publications FG-1 (current edition) standards should be followed while installing a Monterra cable tray. When sawing, drilling, routing, etc., don't use too much pressure. For longer tool life, use drill bits and saw blades with carbide tips. It is not advised to use lubricant while milling. During field cut operations, secure cable trays and fittings properly to prevent material chipping at the cut edges. Observe the directions on the label closely. The strongest and most dependable connections are made using a combination of mechanical fasteners and adhesives.

Support Recommendation as per NEMA Standard

According to NEMA FG1, the splice plate should be placed where the bending moment is zero, which is 1/4 of the span from the support.